The logistics sector is an already experienced industry, however, with increasing new technology the sector is currently in the process of moving towards 4.0. The adoption by the logistics sector of flexible systems - automation, networking, decentralisation and real-time operations, etc. - makes the handling of goods safer, more efficient and less costly.

The logistics sector is an already experienced industry, however, with increasing new technology the sector is currently in the process of moving towards 4.0. The adoption by the logistics sector of flexible systems - automation, networking, decentralisation and real-time operations, etc. - makes the handling of goods safer, more efficient and less costly. Thanks to the integration of autonomous electric vehicles, this move also means that the sector will have a positive impact on the environment. In order to ensure the optimal performance of the various systems, the sector has to adapt and acquire new interface and connection systems for the transmission of energy and data.

As expert in safe, high-quality quick-release connections, Stäubli offers standard or specific solutions to meet the logistics sector’s new requirements.

OPTIMISATION OF LOGISTICS OPERATIONS THANKS TO AUTONOMOUS VEHICLES

When goods are delivered to a logistics platform, they follow a defined route and are repeatedly moved from one area to another: warehouse, shipping zone, loading bay, etc. However, moving goods is costly in terms of time, labour and energy. To reduce all of these costs, logistics operators have increased the use of automated guided electric vehicles (AGV). Powered by batteries, they travel around factories, warehouses and container terminals autonomously and play an important role in lowering the costs of logistics operations while increasing productivity and having a positive impact on the environment.

The optimal performance of these vehicles primarily depends on the logistics platform’s implementation of automated battery replacement systems as well as a high-performance charging point.The reliability and quality of the connections between the vehicles and this equipment ensure that the AGVs are always available, thanks in particular to the rapid and automatic replacement of batteries and the speed of the charging process, which reduces down time.

The Stäubli Group provides its renowed expertise in all-fluids and electrical quick-release connection solutions in order to tackle the challenges associated with the constraints specific to autonomous vehicles in the logistics sector.

STREAMLINED LOGISTICS OPERATIONS THANKS TO STRAIGHTFORWARD QUICK-RELEASE CONNECTIONS THAT AUTOMATE:

- The replacement of batteries

The replacement of autonomous vehicle batteries is managed automatically thanks to the use of robots. In order to automate this task, the power supply systems have to be connected and disconnected easily and quickly without any human intervention.

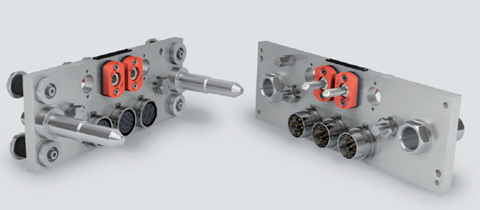

Stäubli’s automatic Multi Connect Systems (MCS) fulfil these requirements perfectly. Multi Connect Systems centralise different fluid and electrical energy sources and connect them in a single movement.

Custom made using standard parts and components, these systems can be configured as required on the basis of the energy sources transferred both for the transmission of power (IP2X safety rating) and BMS data (Battery Management System).

The guide pins and float-mounting elements on the multi-coupling plates make compensate any misalignment to ensure the plates are guided accurately before they are connected.

- Rapid battery charging

To guarantee the continuous running of the logistics operations without any human intervention, the power system must be autonomous and automated.

Charging frequency and duration are adapted in accordance with the application. In order to reduce the battery’s weight and volume on board the vehicle and thus optimise operating costs, AVGs are increasingly equipped with compact batteries that demand short and regular charging cycles. In this case, charging takes place during scheduled breaks or during the loading of goods at the bays placed along the route. An intermediate, short-term charging cycle, known as “opportunity charging”, preserves the batteries more than a full charging cycle.

Stäubli MCS plates comprise an autonomous and automatic actuator that couples the plates to the vehicle and keeps them connected. The guide and float-mounting components compensate any mispositionning of the vehicule to ensure a safe connection.

To respond to the new opportunities that favour the exchange of data in real time offered by logistics 4.0, this system can also incorporate a 10 Gbit module for industrial Ethernet applications, in compliance with CAT 6A requirements.

Stäubli quick-release coupling systems are designed and tested to be used continuously for connection/disconnection operations that are repeated throughout the vehicles’ life cycle. Thus, Stäubli guarantees the reliability and durability of its connection solutions, which boost the productivity and availability of autonomous vehicle fleets intended for the logistics sector.

As the future of the logistics sector moves towards industry 4.0, Stäubli as key player, provides this market with flexible, high-performance and long lasting quick-release connection solutions.