The world is changing. The rule of thumb that investments in concrete and steel will deliver a strong ROI are no longer certain.

Content from our commercial partners

Content from our commercial partners

It is time to challenge the age old adage that IT and infrastructure projects are separate. When planning infrastructure projects, you need to be considering the impact AI and optimization software will have on your overall requirements. Afterall, INFORM’s software-based solutions deliver huge ROI on their own and when factored into infrastructure projects at the planning stage strengthen the ROI proposition of your traditional concrete and steel assets as well. #challengeyourself

From the quay through the yard and onto trucks or rail, INFORM’s add-on optimization modules deliver value across the terminal. With both a strong short and long-term ROI possible, the benefits can be translated into financial terms that have real impact on the bottom line. This article explores the best times to consider software solutions when planning your traditional infrastructure projects.

WHEN SHOULD YOU CONSIDER SOFTWARE?

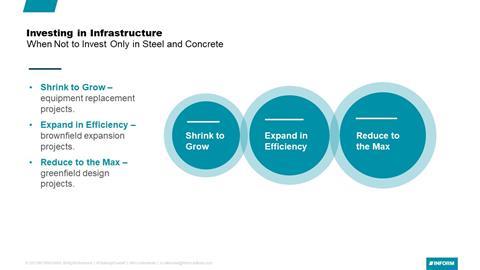

The short answer is quite simple: anytime is a good time because the benefits begin to drive return from the day you go-live. But, the long answer is more structured: given that implementing optimization modules tends to be seen as a capital expenditure (CAPEX) project – albeit with some ongoing expenses (OPEX) – three ideal scenarios align with traditional CAPEX projects where an add-on optimization solution will deliver immediate impact and a strong ROI:

- Shrink to Grow - equipment replacement projects.

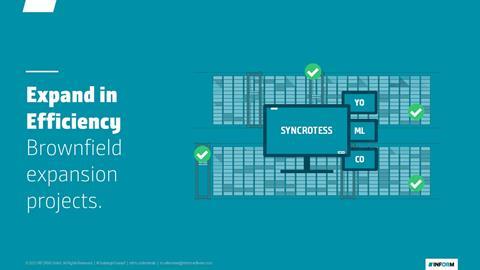

- Expand in Efficiency - brownfield expansion projects.

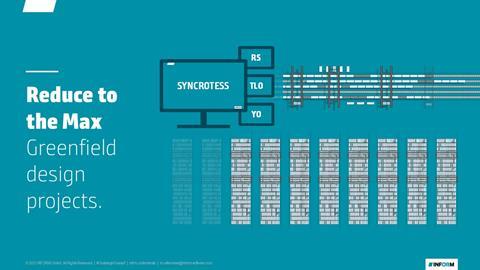

- Reduce to the Max - greenfield design projects.

While each project type is discussed in greater detail below, the general principle is that a small CAPEX investment in optimization modules will pay dividends in the form of both immediate CAPEX project savings as well as through long-term reductions in OPEX costs.

SHRINK TO GROW

Aging handling equipment fleets are an ongoing concern for operations. As equipment ages, maintenance related OPEX rises. On the flip side, new equipment is an expensive CAPEX project that needs to be carefully considered. Traditionally the solution is to replace aging equipment with more equipment – a like-for-like approach. However, this isn’t the only option available to terminal operators today.

Terminal operators should look for the best solution that can both replace aging equipment and do it in a way that improves terminal performance. This would include improving environmental outcomes, improving terminal efficiency, and increasing operational flexibility. Additionally, the outcome should also be financially beneficial to operators (i.e., reducing CAPEX and OPEX costs). While new equipment technologies can tick some of these boxes, add-on optimization can deliver them all.

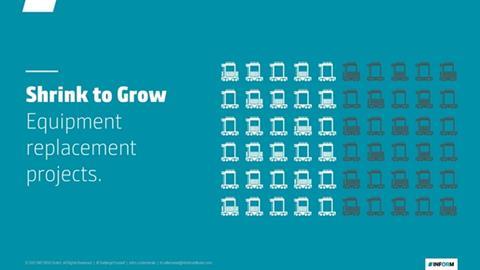

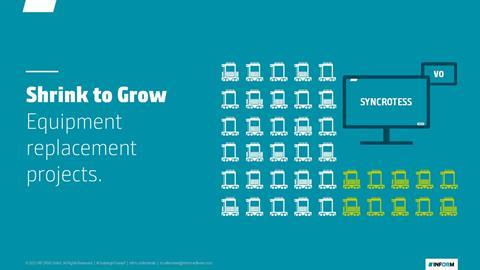

To exemplify this, from a fleet of 60 straddle carriers, 30 need to be replaced.

At a typical European terminal, add-on optimization modules can reduce fleet sizes by as much as 40% while also providing gains in efficiency. This would mean that the terminal could reduce the number of required straddle carriers from 60 to 40, reducing the number of new straddle carriers required to 10. This has an immediate reduction in CAPEX costs and a long-term OPEX cost. Fewer vehicles mean improved environmental credentials. Improved efficiency improves both operational performance in the short-term while also better positioning the terminal to effectively respond to unforeseen future market conditions.

EXPAND IN EFFICIENCY

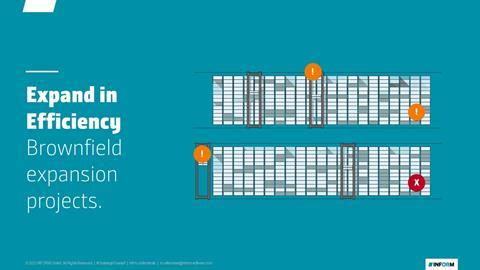

Despite the best planning, all too often terminals find themselves operating at, or exceeding, their ideal operating capacity; this is the trigger for many brownfield projects. Generally, the first reaction to this problem is to build more infrastructure and buy more equipment to service that infrastructure. Never mind, that most terminals don’t have the physical space required to expand their operations in this way; the result? Many projects accept sub-optimal compromises that don’t deliver strong value when weighed against the high investment cost.

Financially speaking, the cost of a brownfield project is significant; to start with, new infrastructure and equipment have a very high CAPEX cost. Then, there will be a permanent increase to ongoing OPEX costs to maintain the new assets. These costs are budgeted against future volume predictions, but what happens if those volumes don’t eventuate as is all too common in recent years? In these situations, terminals are left with higher costs without the revenue stream to justify them which in turn impacts their bottom line.

There is another way. Stop and ask the question: is a physical expansion needed or can we be more efficient with the infrastructure we have? The answer to this question, more often than not, is yes. The very purpose of add-on optimization modules is to allow operators to use their infrastructure and equipment efficiently unlocking existing capacity in the process.

At a typical European terminal, optimization of a 5-high RMG yard’s decision-making processes can result in up to a 50% decrease in rehandles. The flow on effect is that less space is needed to handle the same volume of containers resulting in an increase in the total volume the same physical yard can manage. Similarly, a yard crane optimizer can increase the productivity of existing RMG’s by up to 21% resulting in even further increases in volume handling capabilities. Combined, their effects are multiplied freeing up underutilized capacity all from within the existing infrastructure and equipment.

Sometimes, optimization gains are not enough on their own. In these scenarios, add-on optimization provides the combined ability to boost the utilization of existing assets as well as minimize the quantity of new infrastructure and equipment required.

REDUCE TO THE MAX

When add-on optimization is included at an early design stage, it offers greenfield terminals the highest ROI. By using optimization software, the planning process is enriched with valuable insights into where efficiency can be strengthened and flag potential issues early in the process.

As examples, looking at a typical European terminal’s planning for rail crane infrastructure, it is possible to reduce this infrastructure by up to 25% if planned from an early stage. Similarly, optimization allows terminals to achieve the same volume throughput via yards with fewer blocks. This allows for both the reduction in yard block infrastructure and the equipment needed to service those blocks (see figure 3). Flow on effects touch all aspects of the terminal design and equipment requirements delivering measurable CAPEX and OPEX project savings before breaking ground.

Beyond the immediate savings, this approach allows terminals to grow in a more sustainable way. Opposed to investing in infrastructure and equipment that won’t be fully utilized, it allows these investments to be delayed until demand necessitates them. It also provides terminals with room to expand into the future. If the original design called for four rail cranes, but only three were installed or, twenty-four yard blocks but only eighteen were needed initially - the design and space for the additional infrastructure and equipment are already available for future expansion streamlining those projects when they are required.

Further, terminals stand to benefit from the same flow on advantages seen in both equipment replacement and brownfield projects, including: lowering a terminals environmental impact, improving terminal efficiency, increasing flexibility, and improving performance. Greenfield projects represent the single best time to invest in Optimization modules because the potential ROI is the highest of all project types.

THE POWER OF SIMULATION

To achieve these results, optimization simulations are run based on actual or forecasted data. The representative data is run against a multitude of operational scenarios ranging from low volume, quiet days, through to high volume, busy days. An assessment of the impact optimization will have under these diverse scenarios strengthens the simulation’s ability to assess various possible outcomes. The simulation data is then analyzed and INFORM’s optimization specialists work with the terminals to review the results and work through recommendations.