Increased system availability with condition monitoring solutions by ifm

Our customer

A manufacturer of gantry cranes that are used in the port industry with more than 800 employees is in use with its STS cranes in over 100 ports worldwide. Gantry cranes, aka ship-to-shore cranes as they are called in this industry, facilitate the port logistics and ensure the smooth handling of containers.

Our customer constantly strives to improve the productivity of their cranes in order to guarantee their customers an efficient and economic operation. In the daily routine of logistics remote access via the Cloud is gaining importance, for the port facilities are becoming increasingly complex which makes it hard to keep an overview of processes.

The challenge

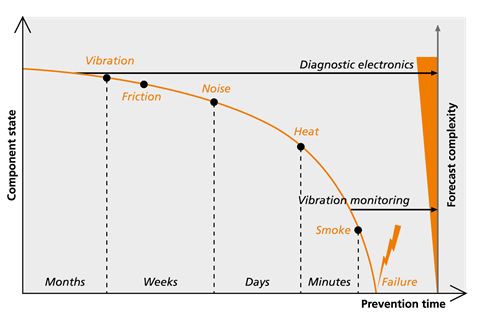

Crane failures pose a major challenge for both port operators and crane manufacturers: When a crane fails, logistics comes to a standstill and high follow-up costs are engendered. Therefore, our customer aims to identify errors preferably at an early stage in order to prevent possible failures. In this context, various data are relevant and especially vibration data play an important role. In the past, they were faced with the problem that the vibration data could only be read out inefficiently.

Monitoring critical components in the STS crane’s machine room is essential for the early detection of problems. Unbalances may occur in drum bearings, gears and hoist motors. If the affected parts fail, the result is a plant standstill, which is often associated with high costs. By using sensor technology, however, these problems can be counteracted at an early stage.

The solution – why ifm?

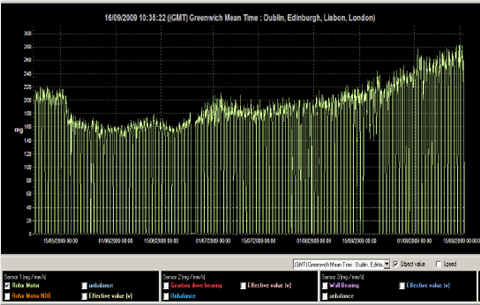

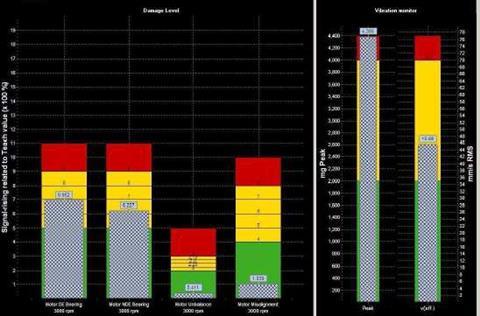

Our customer‘s claim is to ensure crane operation with as little downtime as possible for their customers. A condition monitoring solution to monitor critical components and thus prevent failures must be very easy to integrate into the existing systems and this is exactly what the systems from ifm offer. VSA001 sensors and VSE100 evaluation units are used for this purpose, which allow a reliable analysis of critical machine areas. At the same time, the data is recorded over time.

The evaluation units monitor rolling bearings and gears for imbalances and thus enable a condition-based maintenance in line with the component conditions. A total of four vibration sensors can be connected to one evaluation unit. This allows machine faults to be detected even before damage occurs. The system monitors certain frequencies making it possible to draw conclusions about the machine‘s condition. These frequencies are usually based on the speed of the shaft and the bearing types to be monitored.

|  |

|---|

Background vibrations that have no influence on the mode of operation are not taken into account. Alarm points can be set for each frequency. The measurement can refer to the speed, acceleration and distance, so that the monitoring data becomes even more meaningful. Our customer can analyse the data remotely and provide a targeted maintenance service managed by guarantees and sales.

Results

- Predictive maintenance for the port operators

- High user-friendliness during integration and commissioning

- Condition monitoring solution with the best price-performance ratio on the market

- Cloud solution with ifm RTM software possible in the future

For more information, please visit ifm’s website: Case Study: Gantry cranes less susceptible to defects - ifm